Our new toy, a Matter and Form 3D Scanner, uses its frickin' laser beams

to turn this ceramic head

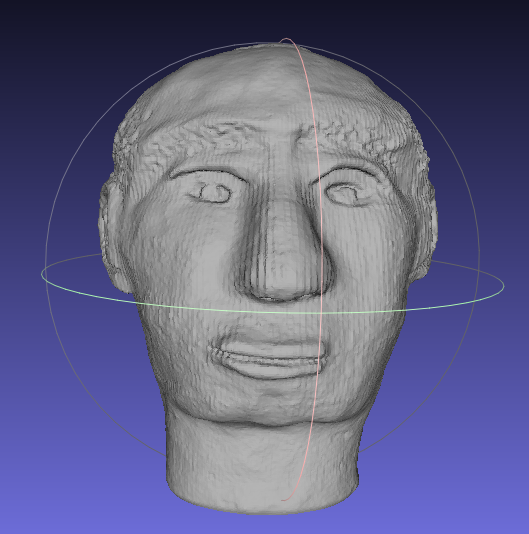

into a digitized 3D object (shown in MeshLab), which we printed with the 3D printer.

Look, we're identical!

Details: The scanner finds a point cloud (i.e. set of three-dimensional data points) on the head. The scanner's software then creates a meshed surface. The surface created was not yet watertight and manifold, meaning that it did not define a printable object. Sometimes the issue is that the object has holes, the wrong topology, or does not have an inside and an outside because the outward normal vectors had some errors (calculus!), so we repaired the surface using the online Netfabb repair service. The fact that the head is a single color and matte (unglazed) makes the scanning much easier. The scanner sweeps up and down, and even managed to capture the nostril holes.

I can remember when they cost millions of dollars!

ReplyDelete